Since the advent of powder spraying technology, it has been widely used in many fields of surface treatment. Powder is different from the traditional liquid coating. For the processing environment and processed products, the processing equipment and process are more environmentally friendly, which meets the requirements and needs of green and sustainable development of manufacturing industry.

In short, the powder needs to be adsorbed on the workpiece by charging, thus forming an effective coating to protect and decorate the workpiece. As a necessary tool for electrostatic spraying, powder electrostatic spray gun will produce high voltage and low current electric field, and the powder particles will carry negative charge when they move in it, and then firmly adsorb on the workpiece to be coated. Therefore, the performance of the spray gun often directly determines the final spraying effect of the product.

Smart 600 electrostatic powder spray gun system

Based on the advanced digital and electrostatic technology, our company adopts the third generation total energy (TCC) electrostatic management system, advanced charging technology and flexible spraying design, forming a good penetration ability. At the same time, using intelligent electrostatic charging and control technology, fully automatic third generation "TCC" total energy charging technology and manual optional "KCC" constant current charging technology, the equipment shows better performance.

The spray gun with good charging performance can charge enough electrostatic charge for the powder particles ejected, so as to obtain enough electrostatic repulsion force between the powder particles. After the powder leaves the spray gun, the powder particles do not adhere, showing a very good atomization state.

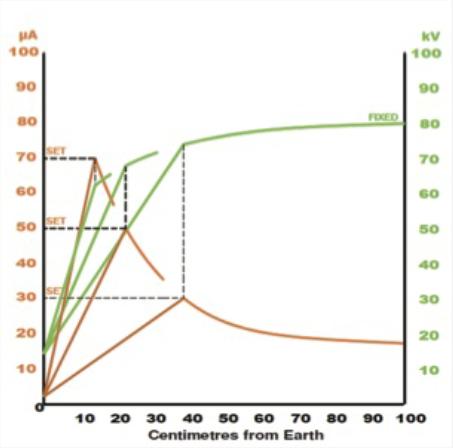

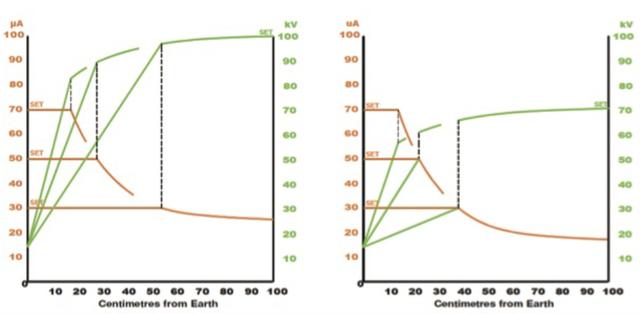

Therefore, the charging mode of electrostatic powder spray gun should have the following three elements: first, the long-distance spray gun should generate higher charging energy; second, the short-distance spray gun should produce lower charging energy; third, it should be easy to operate. The excellent performance of the electrostatic spray gun not only reduces unnecessary waste, makes the powder state uniform and perfect, but also greatly improves the powder loading rate.

Smart 600 spray gun combination charging mode features:

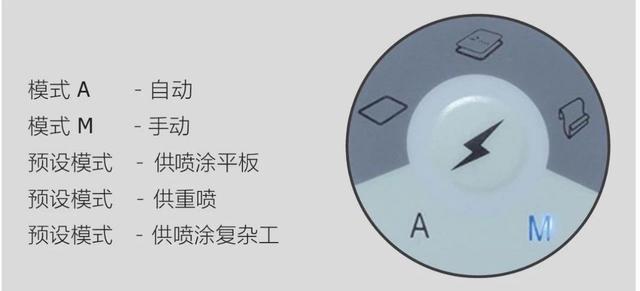

Mode A (automatic) typical equipment

The TCC automatic intelligent charging regulation system can automatically adjust the discharge voltage and current to a better charging value according to the spraying distance, so as to obtain the surface coating and penetration effect with good adaptability.

Mode M (manual) typical equipment

The konstant charge system can cooperate with the operator to make subtle experience settings to adapt to different types of powder and workpiece conditions, so as to improve the powder loading efficiency of the spray gun.

Mode application:

Advantages of charging system:

1. Charging mode: 5 different electrostatic charging modes

2. Remote control: manual spray gun can quickly adjust the control value

3. High reliability: low cost

4. Superior performance: faster and more effective powder loading rate

5. Programmable setting: up to 100 recipes can be preset to save time for repeated adjustment

6. SmartClean intelligent cleaning: efficient and powerful cleaning system of spray gun

7. SmartAir intelligent gas matching: the output gas volume can be adjusted automatically

In fact, the powder loading rate of the spray gun with good performance is high, which can save the powder consumption and reduce the production cost. At the same time, it can also speed up the production, improve the work efficiency, evenly powder, so as to reduce the waste rate and make the production management easier.

Yudong, with 35 years of industry experience, witnessed by more than 1000 + enterprises, has implemented more than 5000 projects, so that we have enough confidence and experience to provide customers with customized coating solutions. Yudong Machinery Co., Ltd. is a reliable solution provider for powder coating equipment.